- About Us

- Our School

- Enrolment

- Faith & Service

- Learning

- Co-Curriculum

- Our Community

- Portal

Saint Ignatius College Geelong

Saint Ignatius College Geelong

A Current Snapshot of the Design and Technology Area

The Design and Technology Area of the college is constantly busy with students working through the design or engineering process to create solutions to proposed problems. Students are provided the opportunity to demonstrate their knowledge and skills through a vast variety of practical activities.

Product Design: Fashion

Currently the students in the Year 10 Product Design Fashion Class are involved in a community outreach program, working on a bag for Barwon Health hospital in Geelong. The bags are called ‘When We Say Goodbye.’ The idea came from a Country Women's Association in Warragul from a registered nurse currently working in Oncology. The idea of the bags came from a need to make the passing of a loved one a little more bearable. The passed loved one's belongings usually get given to the families in a plastic bag. The bags that the student’s are making are more personable and have nice generic designs on the front. The students learn how to applique, french seam and add a drawcord channel, whilst feeling good about the kind deed they are doing.

Mrs Kerry Horbowsky

Product Design: Metals and Wood

Below are samples of senior student’s work, showcasing how they must work through each stage of the design process to achieve a solution to their provided design challenge.

Visualisations and Working Drawings | |

Material Testing and Process Trials | |

Prototyping and Modelling | |

| Production Planning and Production |

Product Design Team

Systems Engineering

The Year 12 Systems Engineering students are finalising their School Assessed Tasks that they have been planning for, designing and building all year, lead by Mr Luis Costa.

Jack Dries: “This year for my Systems project, I decided to create an electronic combination lock. This system is complete with a keypad to register the password inputs, an LCD screen to display some password prompts, a solenoid door latch to lock and unlock the door, and a linear actuator to automatically open and close the door when the password is correct. All of the components contained within the system are controlled through a micro-computer, which needs to be programmed to fit the requirements of the system. Through this micro-computer, it registers the inputs from the keypad, and if the password is entered correctly, the LCD screen displays “The password is correct!”, the door latch unlocks and the linear actuator opens the door for the user. The purpose of this system is to have a secure lock for any door that is completely automatic without the need for a door handle.

Tom Allchin: This year I worked on a remote-controlled cat feeder. The system uses a remote-controlled motor that spins to a metal axle, which turns a wheel to allow the food to fall through into a funnel and then directly into a bowl for the cat to eat.

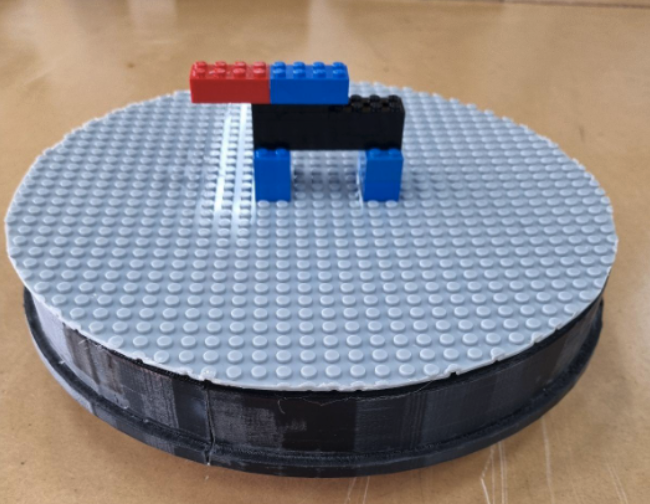

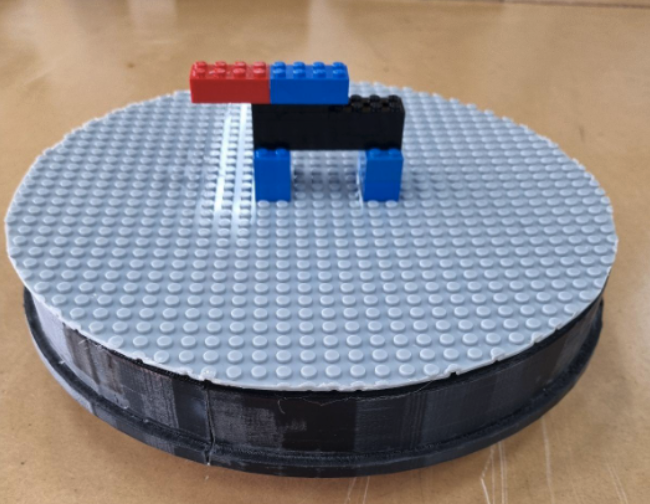

Harrison Work: My project involves creating a Lego rotating display stand, designed to showcase models. The stand is motorised and programmable, allowing controlled rotation at various speeds. It incorporates a DC motor to maintain precision, demonstrating engineering principles like mechanics and automation.

Jackson Brotchie: Reflecting on my Year 12 Systems Engineering project, creating a model train turntable was a rewarding challenge that pushed me to seamlessly blend mechanical design with electronics. This project honed my skills in precision engineering, problem-solving, and project management, solidifying my passion for engineering and the importance of meticulous planning and execution.

Food Studies

After studying food trends and influences to consumer’s food choices, the Year 10 food studies class were set the task to design their own meal kit boxes, complete with an informative recipe card. Students had to undertake a cost analysis to ensure their meal idea would be a profitable recipe for a meal kit business. Their recipes were trialled and tested this week in the Food Studies kitchens. A range of nutritious and delicious meals were produced.

Ms. Leonie O’Brien and Ms. Jaymi O’Connor

Feature

Events

Article by Mrs Kerry Horbowsky

A Current Snapshot of the Design and Technology Area

The Design and Technology Area of the college is constantly busy with students working through the design or engineering process to create solutions to proposed problems. Students are provided the opportunity to demonstrate their knowledge and skills through a vast variety of practical activities.

Product Design: Fashion

Currently the students in the Year 10 Product Design Fashion Class are involved in a community outreach program, working on a bag for Barwon Health hospital in Geelong. The bags are called ‘When We Say Goodbye.’ The idea came from a Country Women's Association in Warragul from a registered nurse currently working in Oncology. The idea of the bags came from a need to make the passing of a loved one a little more bearable. The passed loved one's belongings usually get given to the families in a plastic bag. The bags that the student’s are making are more personable and have nice generic designs on the front. The students learn how to applique, french seam and add a drawcord channel, whilst feeling good about the kind deed they are doing.

Mrs Kerry Horbowsky

Product Design: Metals and Wood

Below are samples of senior student’s work, showcasing how they must work through each stage of the design process to achieve a solution to their provided design challenge.

Visualisations and Working Drawings | |

Material Testing and Process Trials | |

Prototyping and Modelling | |

| Production Planning and Production |

Product Design Team

Systems Engineering

The Year 12 Systems Engineering students are finalising their School Assessed Tasks that they have been planning for, designing and building all year, lead by Mr Luis Costa.

Jack Dries: “This year for my Systems project, I decided to create an electronic combination lock. This system is complete with a keypad to register the password inputs, an LCD screen to display some password prompts, a solenoid door latch to lock and unlock the door, and a linear actuator to automatically open and close the door when the password is correct. All of the components contained within the system are controlled through a micro-computer, which needs to be programmed to fit the requirements of the system. Through this micro-computer, it registers the inputs from the keypad, and if the password is entered correctly, the LCD screen displays “The password is correct!”, the door latch unlocks and the linear actuator opens the door for the user. The purpose of this system is to have a secure lock for any door that is completely automatic without the need for a door handle.

Tom Allchin: This year I worked on a remote-controlled cat feeder. The system uses a remote-controlled motor that spins to a metal axle, which turns a wheel to allow the food to fall through into a funnel and then directly into a bowl for the cat to eat.

Harrison Work: My project involves creating a Lego rotating display stand, designed to showcase models. The stand is motorised and programmable, allowing controlled rotation at various speeds. It incorporates a DC motor to maintain precision, demonstrating engineering principles like mechanics and automation.

Jackson Brotchie: Reflecting on my Year 12 Systems Engineering project, creating a model train turntable was a rewarding challenge that pushed me to seamlessly blend mechanical design with electronics. This project honed my skills in precision engineering, problem-solving, and project management, solidifying my passion for engineering and the importance of meticulous planning and execution.

Food Studies

After studying food trends and influences to consumer’s food choices, the Year 10 food studies class were set the task to design their own meal kit boxes, complete with an informative recipe card. Students had to undertake a cost analysis to ensure their meal idea would be a profitable recipe for a meal kit business. Their recipes were trialled and tested this week in the Food Studies kitchens. A range of nutritious and delicious meals were produced.

Ms. Leonie O’Brien and Ms. Jaymi O’Connor